In industry, there are several types of valves applying to control the flow speed according to our necessary level. One of the check valves is piston check valves . The piston check valve is a controlling type of apparatus using to control the movement of the liquids in the pipe or tube utilizing a straight line of a piston that is a linear flow of liquids or steam.

Usage of Piston valves

The piston check valves are applying in the following areas like brass instruments, pneumatic cannons, stationary steam engines, and locomotive steam engines. Mainly this piston type of check valves is being in the position of 90-degree angle that means vertically. The piston prevents the flow of water or steam as the requiring level.

In brass instruments like trumpet type cornet, flugelhorn, saxhorn here the cylindrical type of piston check valves are using whereas one more type of valve is the rotary piston check valves are using in the orchestral horn and tuba model types of instruments.

In pneumatic canon the piston type of check valve employing to control the flow of pressure. This type of valve also called a spool valve because of the presence of the 2-way-2-position pistons. These types of valves also called a back pressure valve.

In the stationary and locomotive types of steam units, this piston check valves control the pressure of steam as a required level. It can with strand the various temperature levels from -45 degree Celsius to 204 degree Celsius/ -50 degree Fahrenheit to 400 degrees Fahrenheit

Size of the piston check valves and composition of the piston check valves

The various range of the piston check valves from the small size of 2 inches to the large size level 24 inches available at API 6D standard condition and manufacturing on account of the standard institution API, ASME, and ANSI standards. Dimension range 2 inches to 24 inches that means pressure rating class 2500 sizes to class 150 sizes.

The piston type valves are manufacturing with carbon steel, stainless steel, exotic materials depends upon the conditions of applications.

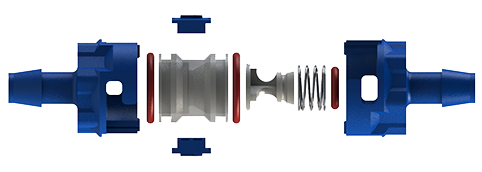

Working principle of the piston check valve

The piston type of check valve has the piston locates inside this piston responsible for the controlling of pressure when comes towards the piston. During pressure of steam, air, the gas pushes the piston and closes the vent it leads to the stoppage of the entry of the steam and others. When the pressure is near the piston it blocks the entry of the steam and automatically releases the piston when the pressure leaves out the piston.

Like our heart pumping system, the mitral and tricuspid valve prevents the return back of the blood flow like the piston check valve also functioning the same that of the heart valve. The piston prevents the return flow supply of the fluid or steam whatever the matters as per what and where we use.

When the pressure behind the piston it blocks the output whereas the pressure or air level decreases automatically return the piston. This principle allows the exhaust of the flow of steam or gas in the pipeline. This piston types of checking valves mainly employing in the gas, steam, air pipeline.